Despite the increasing demand for aluminum welding, there is still a dire need to educate those who wish to take up aluminum welding as a profession.

This has necessitated extensive research into the various methods and processes that are used in aluminum welding. Lightweight, corrosion-resistant Aluminum has long been popular with industrial designers and builders.

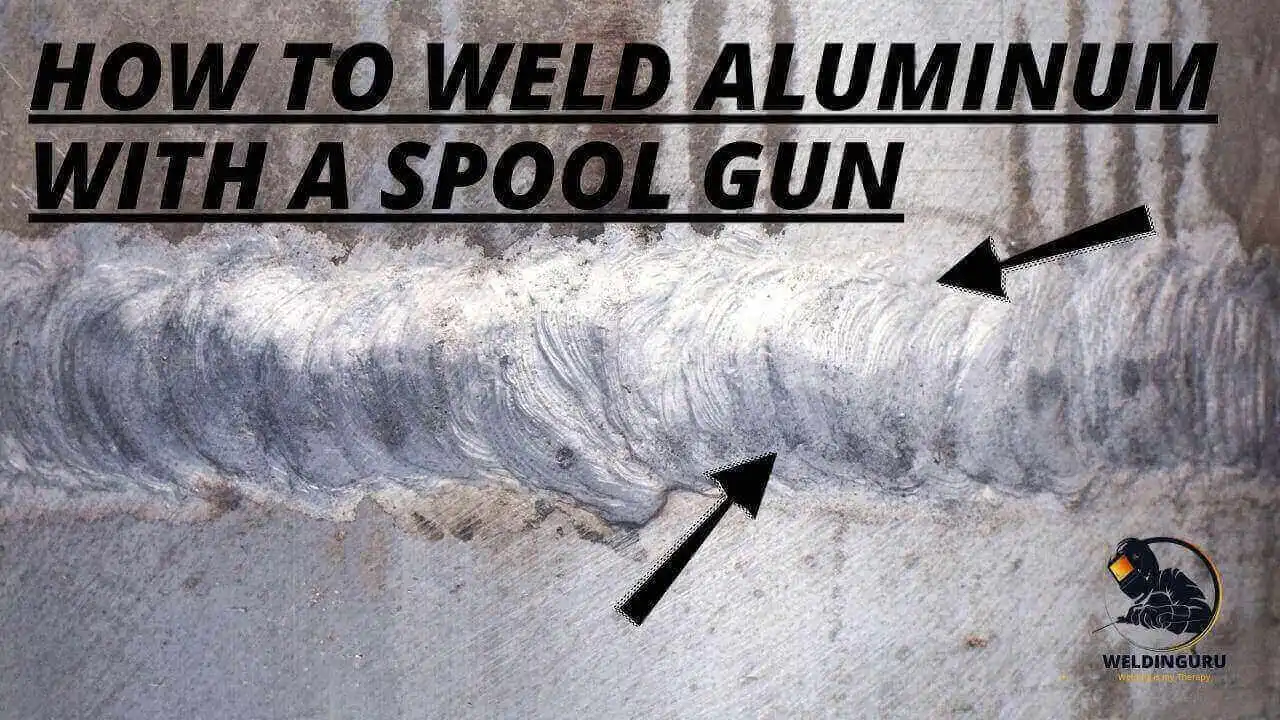

By using the proper welding equipment and following a few important steps, Aluminum can be welded with ease. As a result, aluminum has opened up a whole new world of opportunities, whether you are looking to make jewelry or simply making repairs to your vehicle. This guide will help you use a spool gun to weld aluminum as well as give you some helpful tips.

How to Weld Aluminum with a Spool Gun

A spool gun is a type of MIG Welder that uses a pre-spooled wire instead of welding with a filler rod. The spool gun allows you to weld without having to change out the filler material, so it’s a great tool for welder art or hobby work.

A spool gun can be used for welding aluminum, steel, and stainless steel. You can use a 150lb to 250 lb spool gun and use anywhere from 1/16″ to 5/32″ diameter wire. Some of the advantages of using a spool gun are:

- The spools are pre-wound, so you can start working faster;

- You can change the thickness of the wire simply by changing spools (250lb spools allow you to use up to 5/32″);

- They’re very portable;

- They’re less expensive than flux core welders.

What Is A Spool Gun?

Spool guns are used to feed the wire from spools mounted on the gun. It is a piece of self-contained welding equipment that is specially designed to aid in the feeding of wire. Aluminum wire weighs 1 pound per ft and spool about 4 inches in diameter for feeding.

The spool gun is an essential piece of equipment for every welder who likes to weld with Aluminum. The main component of the spool gun is called the wire feeder head. It has a trigger that allows you to control the speed at which the wire comes out. The contact tip is also another component of the spool gun, and it’s responsible for making contact with the workpiece.

A spool gun is a perfect tool to avoid line tangled problems and save your time. You may think that a welder’s life is inconvenient, but then again, you may wonder how people learn various welding techniques if the switch between Aluminum and steel is so easy. Spool Gun has a lightweight design and compact size, easy to use and carry.

Is Aluminum good as a Welding Metal?

Aluminum offers many advantages to the welder. It is easy to manipulate, can be cut and machined into almost any shape, very lightweight, inexpensive, and readily available. Several different alloys are available, each with varying characteristics.

Aluminum is also extremely good as a welding metal because of its high heat conductivity and surface tension which help hold the molten weld pool in place long enough for the metal to cool and solidify.

Moreover, Aluminum is a great material to use when welding because its heat conducts very well, making the weld pool solidify more quickly. Aluminum is best used with filler metals like 4XXX, 6XXX, and 7XXX series aluminum alloys.

Aluminum Welding

When it comes to aluminum welding, there are a few variables that may impact the end results of the weld. With Aluminum being a highly malleable metal, it is imperative to manipulate the metal in ways that will ensure a smooth and durable weld.

Typically, continuous pressure must be applied to the metal during the welding process. Attempting to push the metal through too quickly may cause an uneven weld.

When using this technique of manual metal manipulation, it is important to note that no other materials besides Aluminum should come into contact with each other.

For example, if an aluminum piece were in between two pieces of wood, it could potentially cause a fire because of the lack of ventilation and poor insulation from the air. It is important to keep this in mind when aluminum welding to prevent injuries and fires from occurring.

Best Aluminum Welding Setup with Safe way

Aluminum Welding – The International Aluminum Welding Society is a not-for-profit professional organization dedicated to developing, promoting, and advancing the science, technology, and applications of aluminum welding.

Apply Nylon or Teflon

The nylon or Teflon in a helically wound liner creates a smooth surface that’s a great environment for aluminum welding. It reduces friction and prevents the Aluminum from being scratched or shaved off. Plus, this type of liner is easy to move around.

Welding aluminum with a steel liner is possible, but the high friction will burn aluminum particles and deposit them onto your weld. This creates a brittle weld that is prone to cracking. To ensure the best quality, you’ll need to use a Teflon or nylon liner for welding aluminum.

Suitable wire

Basic welding tools like wire guides and nozzles are used with the appropriate A/C current when you’re doing pipe welding. Wire guides made of Aluminum are normally used for steel welding, but you should use ones made from nylon or Teflon if you want to reduce the friction and avoid shaving off the Aluminum.

Drive Rolls

You can use v-groove drive rolls for aluminum welding. However, you must have u-groove drive rolls if you want the best welding results. The u-groove drive rolls will not shave Aluminum off when you are feeding it through the rolls.

Instead, they will ensure that the edges of your sheets remain in one piece throughout the entire welding process. You must also reduce the tension on the drive rolls to prevent any rough wear and tear on your aluminum sheets during feeding.

Contact Tips

The consumable parts of the machine, i.e., the contact tips and nozzle, are made of the same material as that of which the machine is made.

For example, the tips and nozzles of welding machines for welding steel and stainless steel are made of carbon steel. For welding aluminum, a nozzle with a larger hole is necessary; consequently, it must be made of more expensive materials like silver, copper, or molybdenum.

Brake Tension

A procedure called aluminum welding can use a lower voltage than steel welding; therefore, the work is not heated much. This technique is positive for a beginner to have practice on, but it is not as strong as steel welds and should not be used on alloys.

Gun Cables

The wire welder is a handheld device used to weld aluminum, usually on thin layers of sheet metal. The operator of the machine must take great care to ensure that the wire does not tangle and remains in line throughout the distance of the liner. This will help ensure consistent flow and prevent irregular welding.

How to MIG Weld Aluminum using a Spool Gun with a Welder

- To produce aluminum MIG welds with a spool gun, a welder needs to have the right kind of spool gun and some spooled wire. The right kind of spool gun is one that has a contact tip that can accommodate the size of the wire. If your welder is a MIG, you’ll need a spool gun to hold the aluminum wire to insert. This can be done by first uncovering the contact tip and canister cover of your spool gun and then unwinding about 10 feet of wire from the protective tube.

- Many people need to weld various materials. Aluminum is one of the most versatile and reliable materials used in creating things at the prototyping level. A spool gun is used to weld aluminum parts with ease. It is used along with the MIG welding process. You just have to clip an 8-inch long aluminum wire and then insert it into the spool gun.

- A spool gun is designed for welding aluminum using a wire feed. Most spool guns are generally made up of three parts: 1) Spool holder, 2) Feeder, and 3) Gun. The process of welding aluminum with a spool gun is the same as conventional welding. Selection of the right types of materials, including contact tips, wires, and nozzles, are needed to perform this kind of task.

- The wire should come out smoothly and at a consistent speed so you can control the speed of your welds. To do this, adjust the tension of the wire using the hex screw on the adjusting point. The size of the screw will indicate how much force to apply it to get a good result.

- Before welding, or indeed cutting Aluminum with an oxyacetylene torch, it is necessary to clean the surface with an aggressive solvent such as acetone. You can use a drill fitted with a stainless-steel brush. Do not use copper brushes: they contain 3 % copper and will cause a difficult weld.

- If you want to be a master at welding, then you need to practice, practice, and practice some more. A great welder always keeps an angle of 1 to 15 degrees while setting the welding torch. This guarantees a sleek look and greatly reduces the chance of soot damage after finishing the project. The cost of getting this wrong can seriously limit your chances of building a beautiful work of art.

- The gun must be placed at least 6 inches away from the base metal to avoid any burns. Use your current handheld tool to weld away all flux left behind. Do not take the welding gun off your welding table before finishing a weld, or you might drop it and damage it.

- A spool gun is an important tool when you want to weld Aluminum. This process requires an argon gas canister, which provides a protective atmosphere to the weld area. The spool gun should be plugged into the positive end of your aluminum welding torch. This will provide a continuous flow of current to maintain stability.

Best way to Aluminum Welding with a Spool Gun

With a good understanding of the differences between MIG welding for Aluminum and MIG welding steel and why the regular MIG welder for steel may not be suitable for welding aluminum, you are ready to learn the secrets of how to weld Aluminum with a spool gun. There are many tips that will help you be successful if you follow them closely.

Density of Metal

When welding with Aluminum of a less than 14-gauge thickness, skinning and scratching occur because the Aluminum is too thin.

Scaffolding around aluminum buildings can be welded using MIG or TIG equipment with a filler metal that has a low aluminum percentage. When completing this task, it is crucial to prevent the Aluminum from shrinking after welding.

Cleaning of metal

Aluminum is a strong and very lightweight metal which makes it one of the most popular choices for material to use for welding. Removing the oxide layer on Aluminum will make it much stronger and more durable.

This oxide layer can be removed with a stainless-steel wire brush, but to be more precise, you should purchase a brush that is manufactured specifically for aluminum oxide removal.

So that, cleaning, when it comes to aluminum welding, is a very important factor in your overall performance. To make a strong weld, the surface you are working on must be clean and free of any debris or impurities.

Argon shielding gas

Argon shielding gas is an inert colorless, tasteless, odorless, and cost-effective shield. 100% argon is used to shield Aluminum in welding due to the lack of chemical reaction between argon and Aluminum for a seamless weld.

The argon gas surrounds what you are welding completely with a blanket that protects against the air, oxygen, nitrogen, and hydrogen.

The shielding gas used in this process is argon, which is an inert gas, making it non-reactive with the molten Aluminum. The excess argon gas can leave the welding area to go through a special trap system.

Course of action

The question of spray mode vs. non-spray mode for welding aluminum is an important one. It depends on the type of transfer you are trying to achieve at the end of the welding process.

Most aluminum applications favor spray transfer over other metal-transfer methods because spray transfer involves the precise and deliberate spraying of molten droplets from the torch tip onto a molten weld puddle.

Due to the high temperature and energy of the arc necessary for MIG welding aluminum, spray transfer will nourish a smooth transfer of small molten droplets of metal to the weld puddle. With low hydrogen in this steel, spray transfer can be used on aluminum thicknesses down to 14 gauge.

Feeding

A feeder can deliver a precise amount of wire to the gun, ensuring that the weld puddle is small and eliminates wasting wire. A spool feeder enables you to deliver a controlled amount of Aluminum to the weld joint that minimizes bird-nesting. A push-pull feeder is an economical tool for long-distance welding when working away from a power source.

What is the best spool gun for Aluminum?

Aluminum is a metal and a good conductor of heat. However, not all spool guns are created equal and be particularly suited for welding aluminum.

Among the best spool guns for Aluminum available on the market are those that are made from Aluminum themselves; some even have an aluminum handle and a non-slip grip.

Aluminum is also beneficial in that it is much lighter than steel and other materials but sturdy enough to handle heavy welding jobs.

Conclusion

After making the investment of purchasing a spool gun, why not take advantage of it and make some money welding aluminum? If you want to be successful at it, you’ll need to buy the right equipment in addition to the gun. Look around online and see what others recommend.

You don’t need all the “best” tools, but you definitely don’t want to skimp on protection since your eyes are very vulnerable when welding. I’ve seen a lot of recommendations for leather welding masks over the $200+ helmets that also offer eye protection.

FAQs

Is aluminum spool gun welding AC or DC?

TIG is the preferred method of welding aluminum because it uses AC current. AC is the better choice for a couple of reasons. First, it helps remove the oxide layer on the aluminum, which helps keep you from forming puddles while welding. Second, it reduces the time it takes to complete a weld.

What is the cheapest way to weld aluminum?

The cheapest way to weld aluminum is with a propane torch and some aluminum brazing rods. Once the rod has melted, gently press it into the joint until it flows out on both sides. With a little practice, you can achieve great looking results in less time than it takes to drive to the welding supply store.

What is the advantage of a spool gun?

Sweep away all your problems. Spool guns are ideal for aluminum and stainless steel, using both SBC and SBC-A electrodes. The design of the spool gun is so advanced that it completely eliminates birdnests and kinking wire, which means you’re going to save a ton of time, money, and material by never having to fix these issues again.

Related Posts: