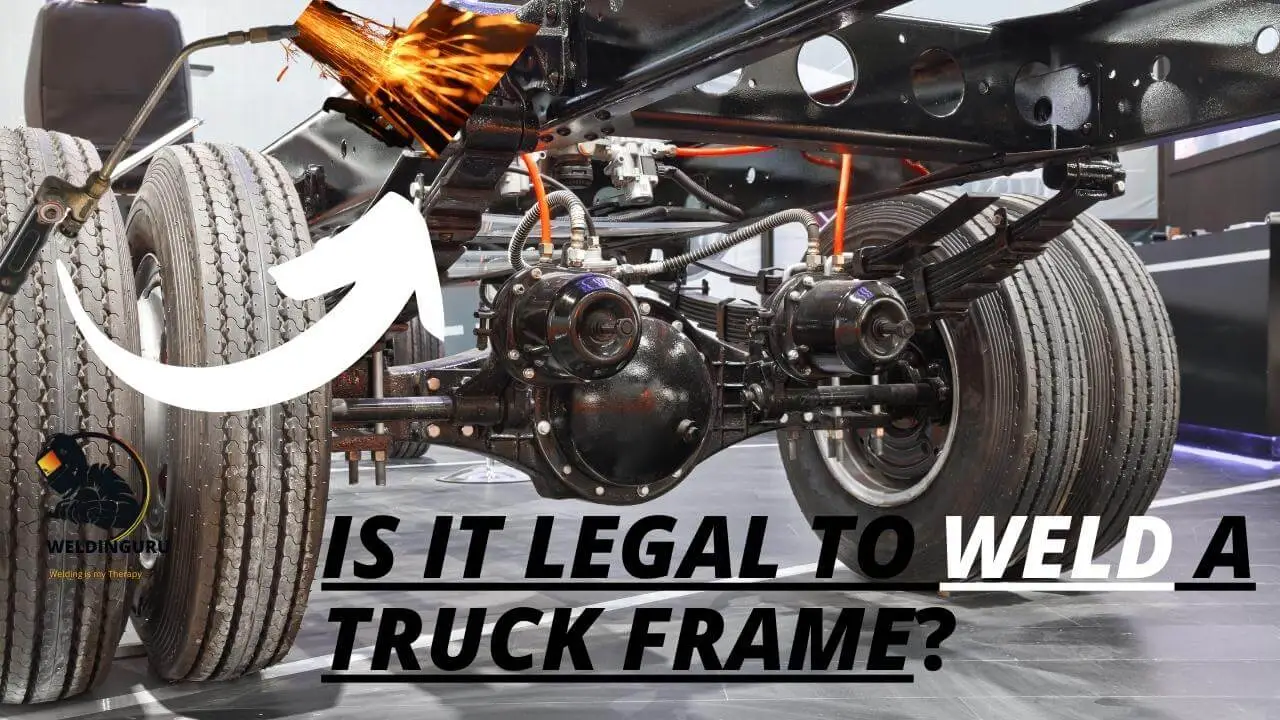

Welding, of course, is an excellent way to repair and reinforce a truck frame. However, it is important to remember that welding anything onto a truck frame (even a replacement for the stock mounting points) can affect the vehicle’s legality.

One of the most common questions asked by truck owners wanting to do welding repairs is, “is it legal to weld a truck frame without repairing official certificates?” No, doubt, it is legal, but only if you do it with proper knowledge and expertise.

In this article, I am going to guide you about the truck and vehicle’s welding criteria and discuss with you the welding legality of both truck & vehicle.

Is It Legal To Weld A Truck Frame?

Welding a truck frame is legal as long as you have the proper certification and training. If you don’t, it’s considered a felony offense. It is important to note that welding a truck frame can be done as long as you are careful and follow all the rules.

The first thing that you need to do is find out if your state allows you to weld your own truck. As long as you have the right equipment and knowledge, welding is not only legal but also recommended.

Welding saves time and money in repair costs over traditional techniques like riveting or bolting parts together.

Welding a truck will not void your warranty unless it’s done by an unlicensed person. If you’re worried about safety, then you should have to hire a professional & experienced person to weld a truck frame.

Also See: Types of Welding Joints

Is it Illegal to Weld a Car Frame?

Welding a car frame is not illegal. However, you should be aware of the safety issues involved with welding a car frame. The first thing to consider is whether you have the proper tools and skills to do the job safely.

You should also check your state’s laws on welding cars. In some states, you will need to obtain a special license in order to weld a car frame.

In order to weld a car frame, you need to know how to use a welder safely. You also need to know what parts of the car can be welded together and which ones should not be welded.

Welding an incorrect part of your car frame can cause it to crack or break while driving, which could result in an accident.

The best thing you can do when welding your car is to hire professionals who have experience with welding cars. They will be able to ensure that your car remains safe for driving after it has been repaired through welding.

How to Weld a Truck or Car Frame?

Welding a truck or car frame is not as difficult as it might seem. When you are welding a large object, it is important to use the right equipment and follow the proper safety precautions.

You’ll need the following things:

- Welding rods in various diameters and lengths

- A welding torch with an oxygen tank

- A grinder for removing rust and paint from the metal frame

- A welder with a cutting tip

- A plasma cutter

- Angle grinder with a cutoff wheel attachment

- Safety goggles

- Ear protection

- Gloves

A few simple steps can help you complete the job safely and efficiently:

Step 1: Preparing the Frame:

The first step in welding a truck frame is preparing it for welding. You’ll need to remove all of the bolts and nuts from the frame and clean it with soap and water, then rinse it thoroughly before drying it off with paper towels.

Once your frame is clean and dry, sand off any rust or dirt patches using 80-grit sandpaper, then use 120-grit sandpaper to lightly scuff up the surface of the metal so that it will bond better when you weld it together again later on.

Step 2: Fixing Cracks:

Now that your frame has been prepared for welding, you’ll need to fix any cracks or other damage in order for your welds to hold up well over time (and keep your car safe).

To start fixing cracks in an old car frame, first, use a hammer and chisel or rotary tool (like a Dremel) to cut through any paint or other coverings on top of the crack; this will make it easier for you to see where they go underneath without having any difficulty.

Step 3: Wear Protective Gear:

Always wear protective gear when working with any kind of electricity sources, such as an arc welder or plasma cutter, since they can cause serious injuries if used improperly or without adequate protection on hand at all times while using them (such as gloves).

Step 4: Use the Right Tools:

Use the right tools for the job. The type of tool needed depends on how much you are welding and what type of metal you are working with. For example, if your project requires a lot of welding, then you will need to purchase a specialized welder that uses flux core wire because it allows for better penetration than solid wire types.

Step 5: Proper Ventilation:

Make sure there’s plenty of ventilation around where you’re working so that fumes don’t build up too much in one area, which could lead to health problems later on down the road if inhaled too much over time (like getting sick from breathing them directly into lungs over time).

Also See: How to Weld Titanium?

Can you Weld a Cracked Truck Frame?

Yes, you can weld a cracked truck frame. However, there are some things you need to know about welding cracked steel before doing it yourself.

Cracks in a steel frame can cause the vehicle to become unstable and dangerous. If the cracks are not repaired professionally, they will continue to worsen and eventually lead to the collapse of the vehicle.

To repair the damage, you will need to remove all of the rust from around the cracks with an angle grinder. Once this is done, you can begin welding your truck’s frame back together by using a MIG welder or TIG welder.

The choice depends on how much experience you have with welding and what type of equipment you have available at home or work (for example: if you work in an auto shop).

After welding up the cracks and grinding off any excess material (to ensure smooth operation), apply rust protection products over the top of your repairs so that they don’t rust again later on down the road!

I personally recommend preferring MIG welding for the purpose of welding a truck cracked frame.

Cut & Shut When Welding a Vehicle Frame

Cut & shut is a term used in the automotive industry to define a type of welding process. In this process, two separate vehicles are cut apart, and their parts are welded together to create a new vehicle. This technique is often used to create custom vehicles or to repair damaged ones.

The most common reason for using cut-and-shutting is when one part of the car needs to be replaced, but it’s not possible to find an identical replacement part.

For example, if you want to replace your bumper but the same model has been discontinued, and there are no more available on the market, you can use this technique instead of purchasing a new bumper from another manufacturer.

Role of FMCSA in Welding a Vehicle Frame

The Federal Motor Carrier Safety Administration (FMCSA) is an agency that regulates the commercial vehicle industry.

The FMCSA is responsible for ensuring that all commercial vehicles are safe and secure, as well as ensuring that drivers are properly trained and qualified.

In the welding of a vehicle frame, it’s important to ensure that all welds are made correctly so that they aren’t prone to failure or cracking. This will ensure that your vehicle is safe for use on public roads.

The FMCSA has established regulations regarding welding processes and techniques used in the construction of commercial vehicles. These regulations cover everything from what materials can be used to how many weld passes must be done before the part can be considered complete.

All welders working on these projects must be certified by the FMCSA or have demonstrated knowledge through previous work experience or training programs offered by companies like ours!

Which Technique is Better for Welding a Vehicle Frame?

I personally recommend going for MIG or metal inert gas welding.

MIG is the most widely used welding process because of its versatility, speed, and ability to handle a wide range of materials. It is also more cost-effective than TIG welding and requires less training to master.

TIG welding uses an electrode that produces an arc between the base metal and the filler wire. This arc is maintained until the filler wire melts, forming a pool of molten metal at the end of the weld puddle. The molten metal then solidifies in this form, creating a strong weld joint.

A MIG welder uses an inert gas (usually argon or helium) that flows through the torch to protect against oxidation or contamination from atmospheric gases, which could cause porosity (tiny holes) in your welds. The flow of gas also provides shielding for your workpiece during welding.

Because TIG requires you to manually control both amperage flow and arc length while simultaneously maintaining contact between your electrode and workpiece, it’s very difficult to master, especially when working with heavier metals like steel or aluminum!

Can you Drive a Vehicle with a Welded Frame?

If you have a vehicle with a welded frame, you may be wondering if it’s safe to drive. The answer is yes. It is safe to drive your vehicle as long as the welds are well done.

The main concern when driving a vehicle with a welded frame is that if the welds break, they could cause the car to fall apart while you’re driving it.

To ensure that this doesn’t happen, you should have your car inspected by a qualified mechanic on a regular basis to make sure that all of the welds on your vehicle are still in good condition and will not pose any threat to you or other drivers on the road.

How Much Does it Cost to Weld a Car or Truck Frame?

On average, welding a vehicle frame will cost anywhere from $1,000 to $10,000, depending on the labor involved and how much time it takes to complete.

The cost of welding a car frame depends on the size of the frame, how much is being welded, and how complicated that welding is.

For example, if you need a small piece of steel welded to your frame, it will likely cost less than if you need a large section of the frame completely replaced.

The more complicated the welding job is, such as when it involves making sure not to damage any other parts of your car during the process, will also increase its cost.

If you want to repair or weld an extensive car damage frame, then there is an expense of $10,000. If you need to weld small damage then there is a maximum expense of $1,000 to $1,500.

Can You Mig Weld a Car Frame?

Yes!

Mig welding a car frame is possible, but it’s not something that you should try without some practice first. The trick to MIG welding a car frame is finding the right settings for the job.

You’ll need to set your wire speed at about 20 inches per minute and use an appropriate gas mix. You should also be sure to use an appropriate tip for the job.

Once you’ve got your settings dialed in, you can go ahead and start welding your car frame together. Just make sure that you have plenty of ventilation in case any fumes escape during the process!

Is it Easy to Sell Welded Frame Vehicles?

It is easy to sell a welded frame vehicle, but there are some things you need to consider first. You will want to make sure that the vehicle is in good condition and that it has been well-maintained.

If the vehicle has been modified or customized, you will want to make sure that it has been done correctly and that no damage was done during the modification process.

The more work it takes for you to get a buyer for your welded frame vehicle, the less money you will receive from them when they purchase it from you.

Is it Safe to Weld a Vehicle’s Frame?

Welding a vehicle’s frame is a process that can be done safely, but it’s important to know what to look for if you’re planning to do the work yourself.

The first thing to consider is whether or not the vehicle has been damaged in an accident. If so, there could be hidden damage that the frame has sustained that you won’t be able to see from looking at it.

You should also make sure that your welding equipment has been properly calibrated and maintained to ensure that your welds are up to standard.

Another important consideration is whether or not you’re using quality materials when making your welds. This will help ensure that they hold up over time and prevent them from rusting or cracking prematurely.

Challenges you Face When Welding a Vehicle’s Frame

Welding the frame of a vehicle is a delicate process that requires precision and attention to detail. It can be difficult to ensure that all parts of the frame are welded together securely, and this can lead to many problems in the future.

1. Alignment Challenge:

The first challenge you face when welding a vehicle’s frame is making sure that all parts of it are properly aligned before welding them together.

When you don’t align your pieces properly, they can end up not fitting together well or even falling apart while driving. This could cause serious injuries if it happens while you’re driving at high speeds!

2. Penetration Challenge:

Another challenge you’ll face when welding a vehicle’s frame is ensuring that your welds have adequate penetration into both sides of each piece being welded together.

You need to make sure that both sides of each piece touch each other so that you don’t end up with gaps between them after they’ve been welded together. This could lead to corrosion problems later on down the road!

3. Right Spot Challenge:

The next challenge you face when welding a vehicle’s frame is going to be finding the right spot for your welder. Depending on how big your vehicle is and where the frame is located, this can be a tricky task. You may need to weld inside or outside of the vehicle or even in tight spaces inside the car or truck.

4. Space Challenge:

Another challenge is making sure you have enough space around your welder so that it doesn’t get damaged while you’re working on it. You’ll also want plenty of room to move around so that you don’t accidentally kick over any tools or knock something over while moving around inside your vehicle.

Different Types of Issues With Vehicle’s Frame

A vehicle’s frame is an important part of the vehicle. It is the part that connects all of the other parts together and helps to keep them in place. There are many different issues that can occur with a vehicle’s frame, including:

Rusting: When the Vehicle is exposed to moisture or salt water, it can begin to rust. This can weaken the frame and make it more likely to break.

Cracking: If there are any cracks in your vehicle’s frame, this can cause problems as well. Cracks can lead to further damage if they aren’t repaired soon after they appear.

Bending: If your car has been in an accident or if someone has hit it with their car (even accidentally), then you might need new parts for your frame because it could have bent from being hit by something else.

There are many other different types of issues that can occur with a vehicle’s frame or chassis over time.

These issues can range from simple cosmetic problems like rusting spots on metal surfaces to serious structural problems like cracks in welds between different parts.

How Can you Know About the Damaged Vehicle’s Frame?

If you’re looking to buy a used car and want to be sure that it has not been in an accident or damaged, there are several ways that you can check.

First, look for signs of repair work. If you see any evidence of bodywork on the vehicle, this could indicate that the frame is bent or twisted. A vehicle with a bent frame will require expensive repairs and might not be safe to drive.

Next, look for signs of alignment issues. If your car’s wheels are out of alignment, this can indicate damage to the vehicle’s frame. This kind of damage is also very expensive to repair and may mean that it’s unsafe for your safety and others as well.

Finally, when inspecting the interior of your potential purchase, look for signs of corrosion or rust on any metal parts like seat frames or door frames. This can indicate that water has leaked into these areas causing corrosion which could cause structural damage if left untreated over time.

Benefits of Welding a Vehicle’s Frame

Welding a vehicle’s frame can provide numerous benefits.

First, welding the frame of a vehicle ensures that it is strong enough to hold up against any external forces. Welding is an excellent way to ensure that your car, truck, or SUV will remain intact in all situations.

Second, welding helps prevent rust from forming on the metal of your frame. Rust can weaken a vehicle’s frame over time, which can lead to serious safety concerns for you and your passengers.

Thirdly, welding creates an aesthetically pleasing finish on the metal of your car’s frame. This makes it look more attractive than if it were simply painted over with paint that chips away easily over time due to regular wear and tears from driving around town every day!

Which Type of Equipment is Required?

Welding a vehicle’s frame is a task that requires the use of many different types of equipment. These include an angle grinder, safety gear, welding clamps, and aviation snips. The body hammers and metal sheet gauge are also required for this project.

1. Angle Grinder:

The angle grinder is used to remove any rust or corrosion on the frame so that it can be welded properly. The safety gear includes protective clothing such as overalls and gloves.

This will protect the welder from injury while they are working in close proximity to heated metal surfaces.

2. Welding Clamps:

The welding clamps are used to hold the frame together while it is being welded together with filler rods made from molten metal, which are placed inside seams between sheets of steel so that they fuse together as one solid piece rather than separate parts which could come apart easily if not handled properly during transportation or use over time due to wear-and-tear factors involved.

3. Aviation Snips:

Aviation snips are ideal for cutting through metal sheets and bending them into shape with relative ease; they’re also great for cutting other types of materials like wood or plastic if needed!

4. Body Hammer:

A body hammer is used during final assembly because it allows you to tap on parts without damaging them with your hands; this helps prevent injury if you’re working near sharp edges or corners (which are common in car bodies).

5. Metal Sheet Guage:

The other piece of equipment that is necessary for welding a vehicle frame is a metal sheet gauge. This device measures the thickness of the metal being welded so that it can be determined whether or not the metal is thick enough to hold up under heat without warping, bending, or cracking.

6. Safety Gear:

The last piece of equipment required for welding a vehicle frame is safety glasses or goggles. These glasses help protect the eyes from any sparks or flying debris that may result from an accidental blowtorch flame burst while working on your project.

Also See: Types of Welding Positions

Things to Consider When Welding a Vehicle’s Frame

When welding a vehicle’s frame, there are several factors to keep in mind.

First and foremost is safety. You need to know how the frame of your car or truck works and what you’re doing with it before you start welding.

You should be familiar with the general structure of the vehicle frame and its components, as well as how to use tools like torches and grinders.

You also want to make sure that your equipment is properly maintained and working correctly before you begin work on your project.

Another key consideration is how much money you want to spend on the project. If you have enough time and patience, you can do this kind of work yourself using simple tools like an arc welder or grinder.

However, if you’re looking for something more professional-looking or durable, it may be worth hiring a professional contractor instead.

Can I Disconnect the Car Battery While Welding Frame?

When you are welding a frame, it’s important to disconnect the battery in your car so that you do not risk a short circuit.

You will need to connect a wire from the positive terminal of the battery to any good ground that is accessible, such as a bolt on the body of the car.

Once you have done this, disconnect the negative cable from the battery and disconnect all electrical components that may be connected to your car’s electrical system. This includes lights and accessories like clocks, radios, and odometers.

Once your car is completely unpowered and safe to work with, proceed with welding your frame according to your local regulations for welding near flammable materials.

Also See: Can Welding Make You Blind?

Different Types of Welding Techniques for Auto Welding

There are several different types of welding techniques for auto welding. It is important that you understand the different types of welding techniques so you can choose the one that best meets your needs.

MIG Welding:

MIG (inert metal gas) welding is a popular method for joining metals. MIG welders use metal wire instead of rods, which makes it easier to travel along a joint and make multiple passes at once.

MIG welding can be used on both ferrous and non-ferrous metals, as well as cast iron, brass, and aluminum.

TIG Welding:

TIG (inert tungsten gas) welding uses an electric arc to melt metal rods or wires together without creating excess spatter or slag, as MIG does.

This type of welding requires more skill than other methods because it requires a steady hand and great dexterity to make sure there are no gaps between the welds that could cause cracks later on down the road.

Spot Welding:

Spot welding is a type of electric arc welding in which an electrode is held against a workpiece and melted by an electric current passed through it.

Gas Metal Arc Welding:

Gas metal arc welding (GMAW) uses an arc between a continuously fed consumable wire electrode and the base material to provide heat and melt filler material to create a joint.

Shielded Metal Arc Welding (SMAW):

Shielded metal arc welding (SMAW) uses an electric arc between the electrode and workpiece that is protected by an inert gas shield; this protects both the weld pool and molten metal from contamination by atmospheric gases such as oxygen or nitrogen.

The shielding gas also reduces heat loss from the weld zone, allowing higher travel speeds for less heat input into the weld puddle than other processes, such as a stick or flux-cored wire cutting.

Also See: Using Nitrogen For Welding

Precautions to Follow When Welding Frame

Welding is a great way to repair vehicle frames, but there are some precautions you should take to ensure your safety and the quality of your work.

- Before you begin, make sure that your welding machine is set up properly for the job at hand. This includes making sure that the unit has enough power and voltage to weld the material you’re working with.

- Make sure that your work area is well-ventilated and free from dust or other contaminants that could affect the quality of your welds or cause damage to your equipment (such as oil).

- Wear protective gear when welding: long sleeves, pants, gloves, and face mask (if necessary).

- You should also make sure that there are no loose wires or other materials around where you plan on working as they may cause sparks or slag, which could damage your equipment or even start a fire if they come into contact with flammable substances such as oil or fuel.

- Make sure that you have removed any oil or grease from the surface of the material being welded. This will help prevent fires and explosions during the process.

Tips for Welding a Vehicle’s Damage Frame

Welding a vehicle’s damaged frame is a great way to repair the damaged metal, but it’s not something that can be done by anyone with some welding equipment.

A professional welder with the right experience and training will have the best chance of success when it comes to this kind of work. Here are some tips for welding a vehicle’s damaged frame:

- Use a welder that is appropriate for the job. For example, if you want to weld metal that is less than 1/8-inch thick, use a wire feed welder rather than an arc welder.

- Make sure you have the proper safety gear (goggles and gloves).

- Make sure you know what type of metal you are working with, not all metals can be welded together, so make sure to research before starting your project!

- Clean your work area and make sure there are no bystanders in the area where you’re working. You don’t want anyone getting hurt by flying sparks or dangerous fumes!

- Read the instructions that come with your welder, so you know how to operate it safely and efficiently!

Also See: Why do Welders drink Milk?

Final Words!

In reality, the answer to the question “Is it legal to weld a truck frame” is most definitely yes.

You can weld on whatever you want as long as you are in compliance with all applicable laws pertaining to your piece of equipment.

Your best bet is to check with an expert and check that you would only be welding something that your equipment was certified for.

FAQs:

Can I weld a crack in my frame?

The short answer is yes. However, it is important to understand what you are up against and take the necessary precautions. Cracks in a frame can be very dangerous to weld, as there is always the chance that the crack will open up again when undergoing heat treatment.

How much does it cost to have a frame welded?

The typical cost to have a frame welded is $600-$1,000 if there is small damage to the frame. This includes labor, parts, and paint. The cost varies depending on the location, the length and thickness of the frame, and whether any rust repair is required.